One of the problems you can face while converting a car from a carb to fuel injection is what to do about the gas tank. On a car designed for EFI, if the engineers have done their job right, the fuel tank will have baffles to prevent the fuel from sloshing around on corners. If you are working with a fuel tank not meant for EFI, the fuel can run to one side while taking a hard corner, and the pickup will be sucking air. Not good. So, if you don't have these baffles, and plan to do any hard cornering with your fuel injected car, you will need to find a way to prevent air bubbles from reaching your fuel rail.

There are three ways to deal with this. If you are lucky, you'll be able to bolt in a fuel tank from an injected version of your car. Or, you can modify your fuel tank to add baffles or a sump so as to prevent fuel slosh. The last option is a bit of a complicated one: Use a low pressure pump to transfer fuel out of your main fuel tank to a smaller surge tank. This surge tank separates out bubbles and has a deep sump that can feed into a high pressure tank.

Well, I can't weld very well, wouldn't want to weld a gas tank anyway, and there are no factory fuel injection tanks out there for A-bodies. Plus, I already have a low pressure electric fuel pump. So I decided to build a surge tank. Big thanks to Lamrith, who showed me how to use a fuel filter as a surge tank. My version has just a few twists added when it comes to flow control. As they say, if it's worth doing, it's worth overdoing.

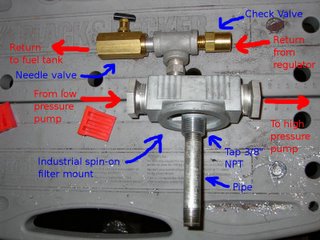

I started with a Goldenrod industrial fuel filter from Tractor Supply. I then tapped the center of the spin-on mount for a 3/8" pipe that reaches to the bottom of the filter. At the top, I drilled a hole in the inlet side so that air bubbles can escape out the top and unneeded fuel can flow through the return. This return hole leads to a tee where it joins the return from the fuel pressure regulator and goes back to the gas tank. Many installations use fuel filters to restrict flow to prevent the low pressure pump from sending gas up the return line; I've substituted a one way check valve. I've also put a needle valve in the return to ensure enough fuel pressure to push fuel through the filter - I may wind up moving the needle valve from the return outlet to in between the top of the fuel filter and the tee, particularly if it creates a spike in fuel pressure. We'll have to see how this works out.

Now, I will have to find a way to mount this vertically and above the fuel pump.

what is your plan to stop the HP fuel pump from over heating? HP fuel pumps use the fuel to keep them cool. You may wont to add an oil cool to the low side of the pump to help keep the pump cool.

ReplyDeleteMany pumps will run fine for a long time without being immersed.I can think of several factory installations that have external pumps.The cooling is a nicety not a necessity.

ReplyDeleteGood Job! :)

ReplyDeleteI don't think either the needle valve or the check valve are necessary.

ReplyDeleteWhat's the difference if the low pressure pump could or would pump some fuel up the return line, The high pressure pump would instantly overcome the low pressure and fuel will flow to th main tank. If the check valve was being held shut by the low pressure pump the same thing would happen, the high pressure pump return would overcome the low pressure and fuel would flow back to the main tank.

The needle valve is not necessary for fuel to flow through the filter. As long as you have about 1 ti 2 psi pressure difference across the filter, fuel will flow. It makes no sense to put UNNECESSARY restrictions in the fuel system, especially on the return line.

Squido says, "when in doubt, leave it out".

As you have it all the usable fuel will be filtered. Any unfiltered return from the low pressure pump will/can be mixed with the high pressure return to the main tank. The high pressure return is also free to return to the surge tank if needed, and be filter again.

I would put a coarse filter in the surge tank and add a fine filter after the high pressure pump.

Squido

"when in doubt, leave it out"

ReplyDeleteI can think of many situations where that would be bad.

"do we need parachutes?"

doctor during operation "i dont remember taking this out"

Do I need condoms?

I really do get a kick out of those who think that a fuel pump is cooled by the fuel around it... it is cooled by the fuel running through it. The fuel passes over the coils in the motor on its way out. There is not enough surface area on the can to do much of any cooling.

ReplyDeleteThink it's a great simple idea that I may well put to use on my 240Z,though with the low pressure/ high volume pump on the inlet with no check valve on the return from the regulator how are you to stop the high pressure/ low volume return from going into the filter? Because the the high pressure pump is only high pressure to the regulator, after this it will drop as it will have little restriction to the tank, and the fuel will find the path of least resistance which will be to tank,so in reality there is no need for a check or restriction on the output from the filter.So really this is simple and effective and adds a filtration section that has a large surface area, that can really be only good.Most high pressure pumps have an inline fuel filter anyway.

ReplyDeleteWould it be possible to feed an underhood surge tank from the mechanical diaphram pump on the side of the motor and eliminate the return altogether?

ReplyDeleteso you can't weld? LEARN HOW TO WELD SON! who would want to weld on a gas tank? Maybe automotive isn't your thing, because plenty of gas tanks have been welded by me and never had a fire, explosion, or problem. When you drain the tank, remove from car and set on ground, you take the tank outside, drain the remaining gasoline out of it, open up all the access points on the tank, then light your torch, and stick your torch in the tank, the tank will go woof once or twice. You go smoke and come back. When you comeback the vapors will have been consumed along with the oxygen in the tank. NEVER EVER EVER use water to rinse out a gas tank. You can't get all the water out of the tank and it promotes rust!! You flush the tank out after the welding is done with safty kleen or varsol and then you do a POR 15 gastank sealing kit and you got a tank that will outlast the car it's in!!!

ReplyDelete