Thursday, December 29, 2005

BMW's Turbosteamer

Turns out, the idea wasn't so crazy after all. BMW has built a device they call the

Turbosteamer, which is a steam engine built into a car's exhaust system. The results were very impressive - more horsepower, more torque, more gas mileage, more thermal efficiency. The only downside was that it added a little bit of weight. Well, and I suppose it wouldn't work too well on a turbocharged engine since they are already using the heat from the exhaust gas. While it won't work with a conventional turbo, it could work with a hybrid gas-electric drivetrain. That might produce some very interesting results when it comes to fuel economy - not to mention have the techie appeal of having a car driven by three different kinds of motors at once.

There's a couple more pictures from the BMW press release making their way around the Internet. From the looks of things, it may actually be possible to pull one off a junkyard car once they show up in junkards and slap them on cars that never had a Turbosteamer. Just take the expansion unit off a BMW and attach it to the crank pulley of another engine with a Gilmer style drive belt, and add the necessary heat exchangers. Probably a lot of fabrication but not any more work than some attempts at adding junkyard superchargers.

Automotive chutzpah!

"Proven tests! Vortex Booster Technology used in Chevy Vortec Engine (Source: Popular Mechanics)"

Well, Popular Mechanics actually did test a Tornado Fuel Saver. Unfortunately, the results were not very good at all. It reduced horsepower by 10% and failed to improve gas mileage at all. Perhaps he's refering to the Vortec cylinder head design... which has nothing whatsoever to do with this intake restriction whatsoever. These things look like they'd be better used for slicing apples than improving engine performance.

Monday, December 19, 2005

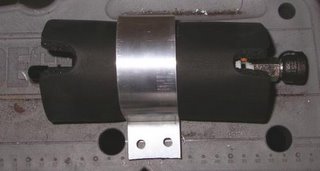

Homemade aluminum bracket for my fuel pump

I built a little bracket for that F-150 fuel pump out of some aluminum strip from Ace Hardware. These brackets are pretty easy to make; the only tools I used were a hacksaw, a hammer, a drill, a center punch, and a vice. Making it curve is easy - just roll it around something cylindrical. The 90 degree bends can be made by simply clamping it in a vice and hammering. You can also see the homemade fitting in the outlet end.

I built a little bracket for that F-150 fuel pump out of some aluminum strip from Ace Hardware. These brackets are pretty easy to make; the only tools I used were a hacksaw, a hammer, a drill, a center punch, and a vice. Making it curve is easy - just roll it around something cylindrical. The 90 degree bends can be made by simply clamping it in a vice and hammering. You can also see the homemade fitting in the outlet end.Labels: Dodge Dart

Surge Overkill

One of the problems you can face while converting a car from a carb to fuel injection is what to do about the gas tank. On a car designed for EFI, if the engineers have done their job right, the fuel tank will have baffles to prevent the fuel from sloshing around on corners. If you are working with a fuel tank not meant for EFI, the fuel can run to one side while taking a hard corner, and the pickup will be sucking air. Not good. So, if you don't have these baffles, and plan to do any hard cornering with your fuel injected car, you will need to find a way to prevent air bubbles from reaching your fuel rail.

There are three ways to deal with this. If you are lucky, you'll be able to bolt in a fuel tank from an injected version of your car. Or, you can modify your fuel tank to add baffles or a sump so as to prevent fuel slosh. The last option is a bit of a complicated one: Use a low pressure pump to transfer fuel out of your main fuel tank to a smaller surge tank. This surge tank separates out bubbles and has a deep sump that can feed into a high pressure tank.

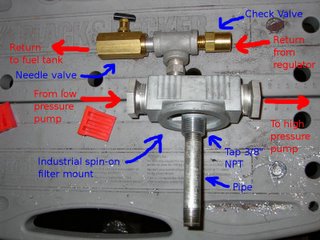

Well, I can't weld very well, wouldn't want to weld a gas tank anyway, and there are no factory fuel injection tanks out there for A-bodies. Plus, I already have a low pressure electric fuel pump. So I decided to build a surge tank. Big thanks to Lamrith, who showed me how to use a fuel filter as a surge tank. My version has just a few twists added when it comes to flow control. As they say, if it's worth doing, it's worth overdoing.

I started with a Goldenrod industrial fuel filter from Tractor Supply. I then tapped the center of the spin-on mount for a 3/8" pipe that reaches to the bottom of the filter. At the top, I drilled a hole in the inlet side so that air bubbles can escape out the top and unneeded fuel can flow through the return. This return hole leads to a tee where it joins the return from the fuel pressure regulator and goes back to the gas tank. Many installations use fuel filters to restrict flow to prevent the low pressure pump from sending gas up the return line; I've substituted a one way check valve. I've also put a needle valve in the return to ensure enough fuel pressure to push fuel through the filter - I may wind up moving the needle valve from the return outlet to in between the top of the fuel filter and the tee, particularly if it creates a spike in fuel pressure. We'll have to see how this works out.

Now, I will have to find a way to mount this vertically and above the fuel pump.

Labels: Dodge Dart

Tuesday, December 13, 2005

Progress with the fuel lines

Today I finally completed the underhood portion of the Dart's fuel lines. Here is a picture of the -6 AN hoses as they pass over the valve cover and onto the inner fender. Note the conduit clamps holding the hose in place at each end. Show car fans may not like this method, but it's cheap and works well.

Today I finally completed the underhood portion of the Dart's fuel lines. Here is a picture of the -6 AN hoses as they pass over the valve cover and onto the inner fender. Note the conduit clamps holding the hose in place at each end. Show car fans may not like this method, but it's cheap and works well.Next, I have to run the fuel lines back to the rear of the car where I will have to mount the Ford F-150 high pressure fuel pump and plumb in a surge tank. My plans for the surge tank are a little bit unusual and I plan on using a couple check valves. I'll probably have to order some of the parts from McMaster-Carr. They're a pretty popular source for unusual parts like that. I also plan on ordering a metal fire extinguisher bracket from them. I've been getting a little nervous about the plastic mounting bracket I had on the fire extingusher that I kept under the Dart's dash, and McMaster's prices on metal mounting brackets are a lot less expensive than many racing shops.

Yeah, I know APC has a chrome-plated fire extinguisher with a metal bracket that isn't too expensive. It's also BC rated, meaning that it is designed to handle handle small gasoline fires or electrical fires, but not burning upholstery. What use is that unless you have a race car with a gutted interior?

Labels: Dodge Dart

Saturday, December 10, 2005

Fuel line work

1. If you want to run a section of steel line through a crossmember and connect both ends to aluminum lines, don't pick a section of steel just barely long enough to go through the crossmember. You won't have much room to use your flaring tool on the ends.

2. 1/2" conduit hangers make a good support for -6 AN hose. They need a little bending to get them to clamp it tightly, but they hold the hose off the sheet metal so it won't rub against that and wear through it.

3. Using these conduit clamps on the AN hose also means that you will help isolate your metal fuel lines from vibration. Hoses are meant to take vibration; hard line isn't.

Labels: Dodge Dart

Tech Tidbits are now organized!

Maintenance is a collection of tips about basic repairs and maintenance. I will try not to intimidate anyone with complex technobabble here. Experienced car guys may already know these, anyway, but I hope that people who just want to keep their cars on the road will find these useful. I have also included tips about tools in this section.

Mythology is where I tackle the car world of urban myths and popular misconceptions about cars.

Mileage is relatively self-explanatory. If you want to burn less gas, take a look at these. Some are rather in-depth, while others may be a bit more easy to read.

Modification is all about making major changes to how your car works - along with some details about the minor steps involved. Much of these currently revolve around Megasquirt and other tips for do it yourself electronic fuel injection. If I run across any interesting discoveries that other hot rodders may find useful, I'll also put those here.

What a Dynamometer Does

Claim: A dynamometer measures torque, not horsepower.

Status: Multiple - depends on the type of dyno.

A dynamometer, or dyno for short, is used for measuring the performance of an engine. These come in several designs. Engine dynos attach directly to an engine on a stand, while chassis dynos measure power at the car's driving wheels. The machinery inside a dyno also comes in several different designs.

The earliest design was a brake dynamometer. Most brake dynos are engine dynos, although it's possible to build a brake-type chassis dyno too. A brake dyno simply consists of a brake mounted on a stand that uses a load cell to determine the torque the brake is applying to the engine. The dyno operator sets the brake to a load that keeps the engine steady, measures the torque and RPM, then moves on to the next RPM point and repeats the process. Horsepower is then calculated using this formula:

HP = Torque * RPM / 5252

An innertial dyno uses the engine or the car's drive wheels to spin a heavy drum. A computer measures the speed of the drum. On an engine dyno, you can then calculate both horsepower and torque from this directly. On a chassis dyno, however, you cannot measure the engine torque directly. On an innertial dyno, you can calculate the horsepower from the rate of acceleration of the drum, while brake type chassis dynos measure road speed and what's known as tractive effort, and calculate horsepower from that. To obtain a torque measurement requires taking the RPM readings and reversing the above formula to calculate torque.

Wednesday, December 07, 2005

Design of experiments and your gas mileage

Sometimes I am much more skeptical about certain devices that claim to enhance mileage than I am about others. I'll be a lot more inclined to believe someone who replaced his original oxygen sensor with a wideband oxygen sensor and reprogrammed his fuel injection to run lean than someone who put a magnet on his fuel line and claimed it made a difference. The difference is that the first is scientifically sound – injecting less fuel can certainly be a reasonable way of burning less fuel. On the other hand, gasoline is not magnetic, so it seems very unlikely that a magnet would affect gas mileage. If you claim that a fuel economy gadget has improved your mileage but the principle the device supposedly works on violates several laws of physics, I will want to see a much higher standard of proof.

To see why this is the case, imagine a doctor has a test that correctly detects a disease 90% of the time. The other 10%, it gives the wrong answer. And suppose that 10% of the doctor's patients have this disease. A little math can predict the results the doctor will have. 90% of her patients will be disease-free. 90% of them will be correctly told that they are healthy. 10% of the healthy patients will be told, wrongly, that they are sick. Of the 10% of her patients that actually have the disease, 90% will correctly be diagnosed. 10% of the sick patients will be told that they are healthy. You can divide the patients into four groups. 81% do not have the disease, and have been correctly told that they do not. 9% are false positives, patients do not have the disease, but have been told that they have it. 9% of the patients do have the disease and have been told that they do. The remaining 1% are false negatives, people who have the disease but were told they do not.

Take a close look at these results. The percentage of patients who actually have the disease and have tested positive is exactly the same as the number of false positives! That means that a patient who has a positive test result only has a 50-50 chance of actually having the disease that the test is supposed to find. In the world of medicine, this would mean that the doctor would order a follow-up test, preferably by a more accurate method. Things would be even worse if only 5% of the population had the disease; in that case, more than two thirds of the people who tested positive for the disease would not actually have it.

The lesson to learn is that if the odds of a device actually working are less than the odds that an experiment will give the wrong results, a good result is actually more likely to be the result of experimental error than it is to be a result of the device actually working. It can be painful to admit a mistake. But this applies to good research as well as bad. If you are testing for something that has a 1 in 1000 chance of working, and your research has a 1 in 100 chance of going wrong, you're still going to have to make it better to be sure your results aren't false positives.

To find out if a change improves your gas mileage, you will need to do your best to eliminate any possibility that the change in mileage is due to any other factor. Here are some important techniques scientists use to make their experiments reliable.

- Measure the original condition (also called a control group) to see how where you are to start with.

- Only change one factor at a time.

- Take as many measurements as you can and see how repeatable the measurements are.

- Measure things with the most accurate measuring device you can find.

- Keep as many things about the test constant as possible.

Consumer Reports has a page where they explain how they test gas mileage compared to how the government tests gas mileage. If you're able to view that page, you will notice that in both cases, the testers try to make their tests as repeatable as possible. The EPA tests cars in a climate-controlled chamber to avoid variations in temperature and humidity that might affect the test. Consumer Reports conducts their tests outside but uses a complex mathematical formula to correct for changes in the weather. The EPA measures how much fuel is burned with a precision instrument that counts all the hydrocarbons coming out of the exhaust. Consumer Reports uses a calibrated fuel flow meter. The EPA uses a pre-programmed test sequence on a chassis dyno. Consumer Reports drives their cars around a test track according to an identical pattern each time. Both of them try to prevent any factor from influencing their measurements, except the car itself.

Most people I've seen who have tested for mileage improvements have some idea of what their mileage was before trying out a mod, so there is not much to elaborate on there. The other points, however, deserve a more in-depth look.

One factor at a time is also relatively self-explanatory. If during one tune-up, you replace the spark plug wires with new ones, install Splitfire plugs, replace the oil with Mobile One synthetic, put in a Tornado Fuel Saver, fit your car with water injection, and replace a burned out oxygen sensor, you won't know which of these has caused any change in gas mileage. In fact, you may have even put in something that could have caused your mileage to go down along with changes that improve it. Serious car guys will note that the list of changes above is a deliberate mixture of measures that may work along with some that are almost certainly scams.

The repeatability of measurements is a much more common issue with amateur gas mileage experiements. If you've kept track of your car's mileage over many tanks, you've probably noticed that it rises and falls depending on what sort of driving you have been doing, and possibly due to other factors such as climate. For example, my Focus usually averages around 28 in the sort of driving I do. Suppose I install some sort of gizmo and find the next time I fill it up, I have recorded 31 miles per gallon. If I just stopped there, it seems like I've had a 3 mpg increase – not bad. Unfortunately, I've measured as low as 25 mpg and as high as 33 mpg without making any changes to the car itself. A measurement of 31 mpg may just be a fluke due to differences in how I have been driving it.

Accuracy of the measurements is also an issue that sometimes trips up the unwary. One well-meaning tester tried to assess the effectiveness of a mod by judging how many miles his car could go before the gas gauge reached Empty. Unfortunately, normal gas gauges are not very well calibrated instruments. On my Focus, an Empty reading seems to mean I could put in anywhere from 11 to 12 and a half gallons of fuel.

So, what is a precise indicator? If I were doing tests, I would love to get my hands on a genuine miles-per-gallon gauge that has a flow meter in the supply and return fuel lines along with tapping into the vehicle speed sensor. If your car has a built-in miles per gallon trip computer, that will probably also work reasonably well. A gas pump's volume measurements are very precise, although it does not always shut off at exactly the same point. But it's pretty close. One test by Popular Mechanics ran the fuel tank dry and then filled it with a carefully measured amount of gas – a technique I'd only repeat if I could shut the fuel pump off as soon as the tank ran out, and had a container at ready to refill it.

Holding all outside factors constant may be one of the trickiest things to do. If you are just measuring your miles per gallon every time you fill up at the pump, you'll have been driving through different kinds of traffic, in different weather, over different terrain each time. And you may even be putting a different blend of gasoline in the tank, as they change the ingredients a little depending on the time of year. Averaging over many tanks may be more accurate, especially if you switch out whatever it is you're doing to try and change your mileage each time you fill up. That way you won't make the mistake of testing your car unmodified in summer and modified in winter, and find that the change in mileage was due to the onset of winter instead of the changes you made to the car. Or due to something on your car wearing out at about the same time you installed the mileage gadget.

Some tests I could see working without any special equipment would include making several passes over the same stretch of pavement going the same way while carefully recording the readings on a mileage gauge, or pouring a measured quantity of gas into the tank and driving it around a flat oval at constant speed until it runs out of gas and using the trip odometer to see how far the car drove. Using cruise control to hold the car at constant speed can eliminate one more source of human error. With a little creativity, you may be able to come up with some other rigorous testing methods if you keep the principles of accuracy and repeatability in mind.

Tuesday, December 06, 2005

Windshield washer fluid

I also thought I'd pass along a minor tech tip, particularly for those like me who live in warm climates but occasionally have to deal with ice. Windshield washer fluid comes in many freezing points. While out shopping today, I found some rated for 32 degrees F, some for 22, and some for -20. (For those who prefer Celsius, that's 0, -6, and -29 degrees, respectively.) The lower freezing point doesn't just keep it from freezing in the winter, though - it helps melt the ice off your windshield. The lower the freezing point, the less washer fluid it takes to completely melt the ice. Some of the summer washer fluids will hardly melt ice at all.

Now that I've heard some of the newer Buicks have heated windshield washer systems, I'm starting to wonder what it would take to retrofit such a system onto a car that never had it. I suspect it might be pretty easy... at least compared to my current projects!

The Myth of One Wheel Drive

Claim: An open differential is only one wheel drive.

Status: False.

You've probably seen a car stuck in the mud or snow with one wheel spinning and the other wheel standing still. It's easy to assume that the drivetrain must only be connected to one of the wheels. The reality is much more complex. A normal drivetrain drives both wheels at the driving end (or all four wheels if you're talking an all wheel drive car), but they are not connected with a rigid shaft.

Since the wheels turn at different speeds when going around a corner, a car needs to use a system of gears that permit the driving wheels to turn at different speeds. The cheapest way to accomplish this is to use an open differential, which is a system of gears that sends equal torque to both drive wheels. If you put both drive wheels on a two wheel drive in the air and run the engine, both wheels will turn unless the brake on one wheel is stuck.

The problem with an open differential is that it can only send equal torque to both wheels, except for some very slight differences caused by friction. And it cannot send more torque to either wheel than the wheel can put to the ground. Consequently, if one wheel slips, the differential can only send it a very small amount of torque. However, it is not able to send any more torque to the opposite wheel, since the torque must be equal. Consequently, an open differential is either two wheel drive - or no wheel drive.

Limited slip differentials can often send torque to only the wheel that has traction while sending no torque to the other. It may seem counterintuitive, but a differential that locks up and moves both tires instead of one is temporarily acting as a one wheel drive system.

If both wheels have equal traction, an open differential does not have to spin just one wheel. Gary Donovan's 10 second Plymouth Reliant demonstrates that you can smoke both tires and lay two patches of rubber even with an open differential.

Howstuffworks.com has an article on what's actually in a differential, complete with animated drawings.

Monday, December 05, 2005

A reader's concern

Interesting web site. I would like to make one comment. I have

only looked at your site for a couple minutes, and read:

“the inlet uses a

3/8"-24 bolt thread. Ford dealers won't sell the fitting that screws in there

apart from a $200 fuel line”

Don’t forget places like “Russell’s” and

“Earl’s” for unusual fittings. Personally, I would not like something

“soldered” together. Too much vibration and such to trust that. I am

sure someone makes the fitting you need.

Tom

I appreciate his concern, and would like to make it clear to my readers that when I made a fitting to adapt my Ford truck fuel pump to my fuel lines, I did joined the pipe cap to the threaded bolt mechanically by drilling and tapping the end of the pipe cap for 3/8"-24 threads. The solder is being used only to seal out leaks. Unfortunately I have not found an off the shelf fitting designed to connect this thread to tubing or -6 AN hose, even after searching several fitting websites. I did find that the 3/8"-24 thread appears on -3 AN hose, so it may be possible to use a -3 flare to -6 flare fitting to stick an AN hose on this pump directly. You'd probably want to use a copper washer on the -3 side (another suggestion made by Tom) to seal it.

BTW, Tom has a Corvair with some pretty creative mods that you might want to check out.

Labels: Dodge Dart

Thursday, December 01, 2005

Why do people drive like this?

But it seems I was wrong again; he kept the hazard flashers on for the next several miles, until he turned off the road I was following. Apparently the driver was simply in the habbit of driving with the hazard flashers on. It's not the first driver I've seen who was doing this, either, driving along at normal speed with no obvious problems but the hazard lights blinking anyway.

Why is it that people drive like this? Are they simply so inattentive that they don't notice the clicking of the relays and the blinking lamps on the dash? Are they trying to warn everyone that they are hazardous drivers?

I just don't get it.

A few more Megasquirt questions and answers

Is Megasquirt a stand-alone controller or a piggyback system?

It's a stand-alone. Megasquirt can control both fuel injection and spark timing directly. If the original computer in your car only controls fuel and spark, you won't need it anymore. Some buildups do retain the stock computer for other functions, though. Megasquirt does not normally control such things as gauges, ABS brakes, or automatic transmissions, which some factory ECUs control.

Megasquirt is not designed to intercept signals from the stock sensors and send different data to the stock computer, like a normal aftermarket piggyback system. Megasquirt can be configured to fire a second set of injectors while the ECU controls the original injectors, but this is usually only desirable if the original injectors are very unusual and difficult to control.

Can Megasquirt work even if my engine has sequential fuel injection?

Most engines with sequential injection use it mostly for emissions purposes and an ultra-smooth idle. In normal cases, the engine will still run quite happily with the injectors rewired to run in a batch-fire or bank-fire configuration. However, if you have a diesel engine or one that injects gasoline directly into the cylinders, you will need to keep the sequential injection. Currently you will not be able to use Megasquirt with this sort of system, although this is likely to change in the future.

What do I do with my MAF sensor?

Megasquirt is normally a speed-density system and does not need a MAF sensor. Instead it uses a MAP, manifold absolute pressure, sensor. You can remove the MAF sensor unless you also have the stock ECU onboard and the stock ECU needs it. It is possible to program Megasquirt to work with some types of Ford MAFs, but this is only necessary for a few special applications.

Will Megasquirt pass an emissions test?

That depends on what emissions tests are required of your car. If you live in California or other places with similarly strict visual inspections, Megasquirt will be trouble. Megasquirt does not have a CARB EO number, and it has enough potential for mayhem that it is not likely to ever have one. California emissions inspectors will not certify your car if they find you are using a Megasquirt to control the engine.

Many Megasquirt users report being able to pass a sniffer test with careful tuning. If everything on your engine is functioning OK and you have not installed mods that would make passing a tailpipe test difficult, this kind of test should be no problem for normal emissions standards. If your car needs to comply with extremely stringent standards such as ULEV or PZEV, tuning to pass a tailpipe check will be more difficult.

Many states test OBD-II equipped cars by connecting the stock ECU to a diagnostic computer. For this test to work, the stock computer must be in place, functioning, and not detect any problems. Of course, the stock computer need not actually be controlling the engine for it to report that everything is functioning. Some of them will not put out any codes if they are simply hooked to stock sensors and the sensors are not reporting any problems. Others may require connecting the computer to resistors in place of the stock injectors so the computer will "think" it still has a full set of injectors.

How hard is it to solder this thing together?

I had almost no soldering experience prior to assembling one of these things, but I got it assembled in about eight hours of soldering.

Do I need any programming skills to run this?

Not really. While the assembly is do-it-yourself, the programming has already been done.